In accordance with OSHA Standard 29 CFR 1910.147, employers are required to establish a program to ensure that before any on-site machine or equipment is serviced where the unexpected energizing, start up or release of stored energy could occur and cause injury, the machine or equipment shall be isolated from its energy source and rendered inoperable to prevent injury.

The servicing of machines or equipment may expose the employee or contractor to serious physical harm or death if hazardous energy is not properly controlled. Types of hazardous energy include, but are not limited to: electrical, mechanical, hydraulic, pneumatic, chemical, and thermal.

The servicing of machines or equipment may expose the employee or contractor to serious physical harm or death if hazardous energy is not properly controlled. Types of hazardous energy include, but are not limited to: electrical, mechanical, hydraulic, pneumatic, chemical, and thermal.

To protect workers from the hazards associated with machine or equipment repair, the employer must establish, implement, and enforce a site-specific Hazardous Energy Control written program consisting of:

- energy control procedures;

- employee training; and,

- periodic inspections

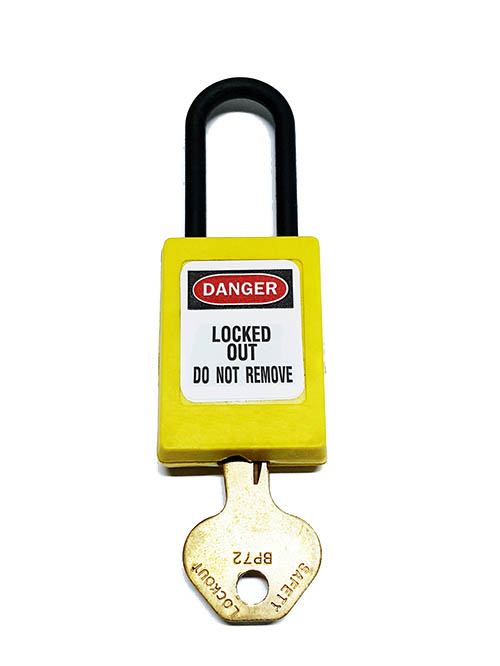

Hazardous energy control is achieved by installing lockout and/or tagout devices. The physical protection offered by the use of a lockout device, when supported by the information provided on a tag, provides the greatest assurance of employee protection from the release of hazardous energy. Lockout devices are usually either red or yellow in color and have a distinct place to attach a lock. Lockout devices must be substantial enough to minimize the likelihood of early or accidental lock removal, and, as such, only authorized employee(s) are permitted access to lockout keys. In addition to installing a lockout device, tagout tags provide an information source pertaining to the hazardous energy control process. Tags must be legible and understandable by all employees. Tag must warn against hazardous conditions if the machine is energized and offer employees clear instructions such as: “Do Not Start,” “Do Not Open,” “Do Not Energize,” or “Do Not Operate.”